More than just quality.

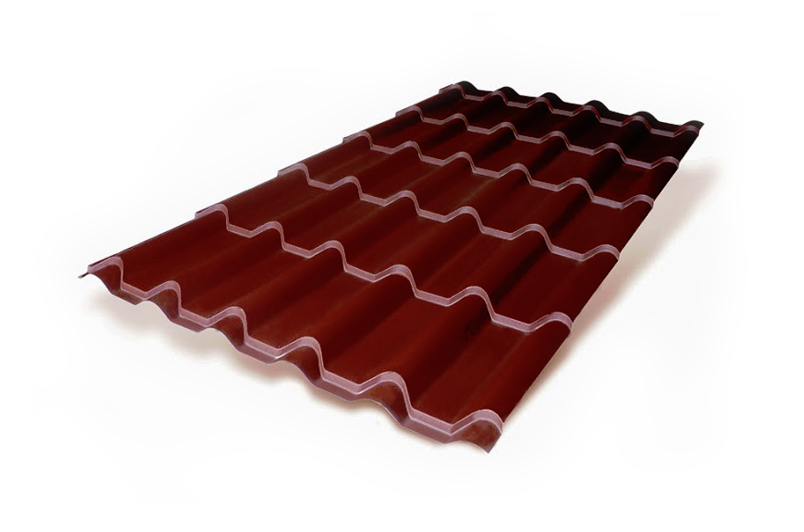

Best pre-material

It is necessary to utilize Voestalpine’s top quality steel strips along with the best brands of pains sourced from European manufacturers to produce a colofer®. Our integrated steel mill located at Linz allow us to have total control at each step of the process ranging from the initial iron ore to culminate in finishing via paints.

Consistent top quality

The quality of the different products used greatly influence each state of the production cycle as well. We have the most modern equipment as well as the high precision procedures for measurcalgaement employed at every single stage of the production thus enabling us to produce the best quality colofer® at our Linz facility. Our customers gain advantage courtesy the top rated quality products that happen to be compliant with the requirements too.

Testing & Development

The colofer® is tested extensively by exposing it to a wide variety of locations regularly. It meets the challenges admirably even when tested in extreme conditions. It is therefore proved that our products are second to none when it concerns quality. Moreover, our team of scientists strives to improve it further by working relentlessly on developing it further.

The Eco-Pioneer

Our colofer® happens to be a leader when it comes to protecting our environment and safeguarding the health and wellbeing of our teams. Voestalpine has already come up with a plausible solution that address the environment concerns by removing chromate and chromium completely from the process without compromising its quality and jeopardizing the guaranteed benefits. It has thus been recognized as a leader by its superior operation of the steel making process across Europe without posing any harm to the environment.

Why is the letter f in the colofer® logo green?

Eco-friendly steel manufacturing plant

Protecting the environment is our primary focus. The Voestalpine Group of Europe has come to be considered as a standard for curbing harmful emissions and ensuring the use of resources efficiently. Voestalpine keeps working continuously for reducing the carbon footprints by trying to enhance energy efficiency in keeping with the technological advancements.

Environmentally compatible coil coating line

The colofer® coil coating process has succeeded in being the best year after year thereby being regarded as a standard within the industry. It has worked untiringly to decrease the amount of CO2 release, adopt safe water treatment practices, and elevate energy efficiency in order to satisfy the “European Coil Coating Association” that reviews the working processes of almost 90% of the companies of the industry.

Top performance

There is absolutely no need to choose between protecting the environment and enhancing the performance, colofer® manages to do both effortlessly. Our applications meant for RC5 environments come with a guarantee of 50 years thus establishing our claims. We have come a long way by building upon our experiences and are looking forward to more solutions to take on the challenges of tomorrow convincingly.